Motor vehicles have metal plates attached that are generally known as license plates; however, this is a wrong term.

As you know, the driver must be licensed, and the vehicle must be registered; that’s why you call them registration plates. In the South and some other states, the plates are typically named as license tags. Whether it is in the metal or the form of stickers, whatever is mentioned on the plate, simply informs authorities about the vehicle registration and the owner.

For motor vehicles, the American states and Canadian regions have different sections that deal with coloring, issuing, and numbering the plates. In color combinations, captions, and words imprinted on the plates, further divisions are made for law enforcement.

The license plate holds multiple information including weight, registration validity, classes of vehicles, and details about the owner.

Things Needed to Make a License Plate

In the list of raw materials used to make license plates, you need aluminum sheets, paint, adhesive sheeting, preprinted, and colored reflective sheets. Metal manufacturers cut the aluminum blanks in size to deliver it in the form to plate makers and other organizations.

Specialty printers are used for county designation and registration renewals on reflective sheets similar to cover the license plates.

Design

The license plates’ design is not boundless to the typical size and width that gets fit in the license plate escalates. Moreover, some features such as color and reflective covering are incessantly enhanced for visibility to help in law enforcement.

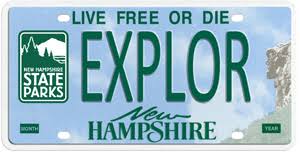

Apart from these limitations, the design of license plates may be somewhat creative.

Do you know that personalized plates have become eminent in the last three decades? Yes, it happens when the states accepted the profits of engaging to the uniqueness of the public. In Canada, vanity plates are known as personalized number plates (PNPs). The revenue generated from the vanity plates in California is reserved for environmental projects; that’s why these plates are known as environmental license plates (ELPs).

The Manufacturing Procedure

We have two different manufacturing procedures, the first one is the old method, and the other is the new one.

Let’s dive into it:

Old Method

The correctional organization is the top-notch source of most license plate manufacturing. Well, some private companies are still on the list that people search for manufacturing.

At first, you need to insert metal blanks into presses and then trample with round edges as well as a couple of characters. Generally, both numbers and letters are used in the stamping.

Next, the plate is painted with the primary color, and then elevated characters are painted with some contrasting colors. An automatic roller is used for painting the edges and characters. The roller gets fixed at the right height to paint raised elements.

Then the two-colored plate is processed with reflective covering, which is made of delicate glass beads that bend light and spring up back continuously.

New Method

A preprinted sheet is used in the manufacturing of modern license plates. The sheet helps in un-stamping the metal blank. The sheet has the prominent color of the plate along with different colored decorations. In the covering, it has reflective material on the sheet.

The sheet and the blank get fixed. In order to make the raised characters, the sheet covered blank is embossed while the characters are colored with ink.

Next, the ink lets the reflective material brighten up thoroughly so that plates can capture full details. Keep in mind that the ink is not much hard-wearing as compared to the paint. The reflective sheet helps make the license plates convenient for law enforcement officials to see the number plate while using headlights or flashlights.

The whole process ends and shows how it makes the number plates manufacturing expensive.

Quality Control

Departments of state motor vehicles make some policies for manufacturing license plates by following the State legislature’s direction. When talking about interstate traffic, taxes, and licensing, some rules exist to manufacture plates as per the Interstate Commerce Commission.

The state motor vehicle authority approves the numbers and letters on vanity plates, number designations, and special interest plates before the manufacturing. The state motor vehicle is the primary source that deals in private companies as well as correctional institutions. You need to follow the rules and criteria to fulfill the quality control checklist.

While manufacturing, the observation comes under the quality control phase. In this phase, the embossed metal plates are examined in terms of covering and painting before packing and delivering.

License plate manufacturing is not an easy thing, as it takes a lot of time. You need to spend hours before getting the final notification of your plate’s approval. Once your plates are approved, you are all set.

Keep yourself updated and enjoy vanity plates.